Service to Printers

IberoWIN Bar System

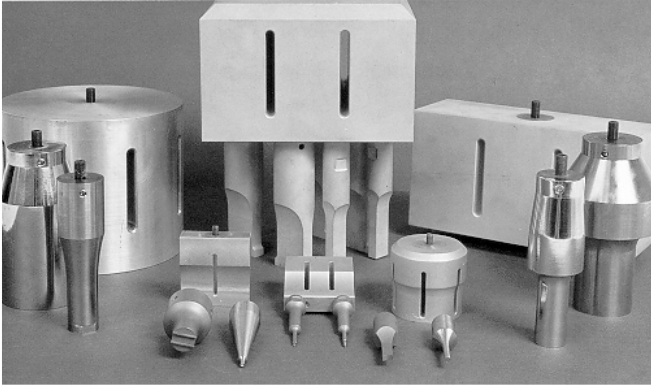

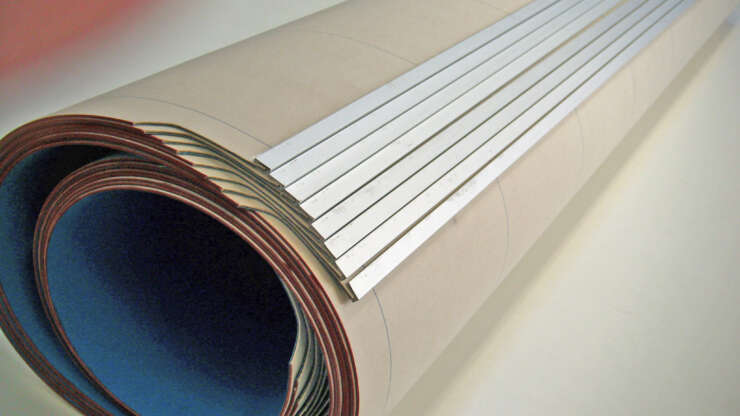

Most Printing Blankets with Bars and Flat Bars converted according to IberoWIN Conversion System use in-house designed aluminium Bars.

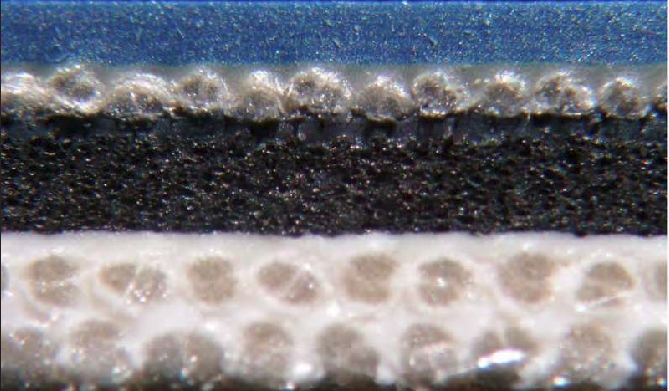

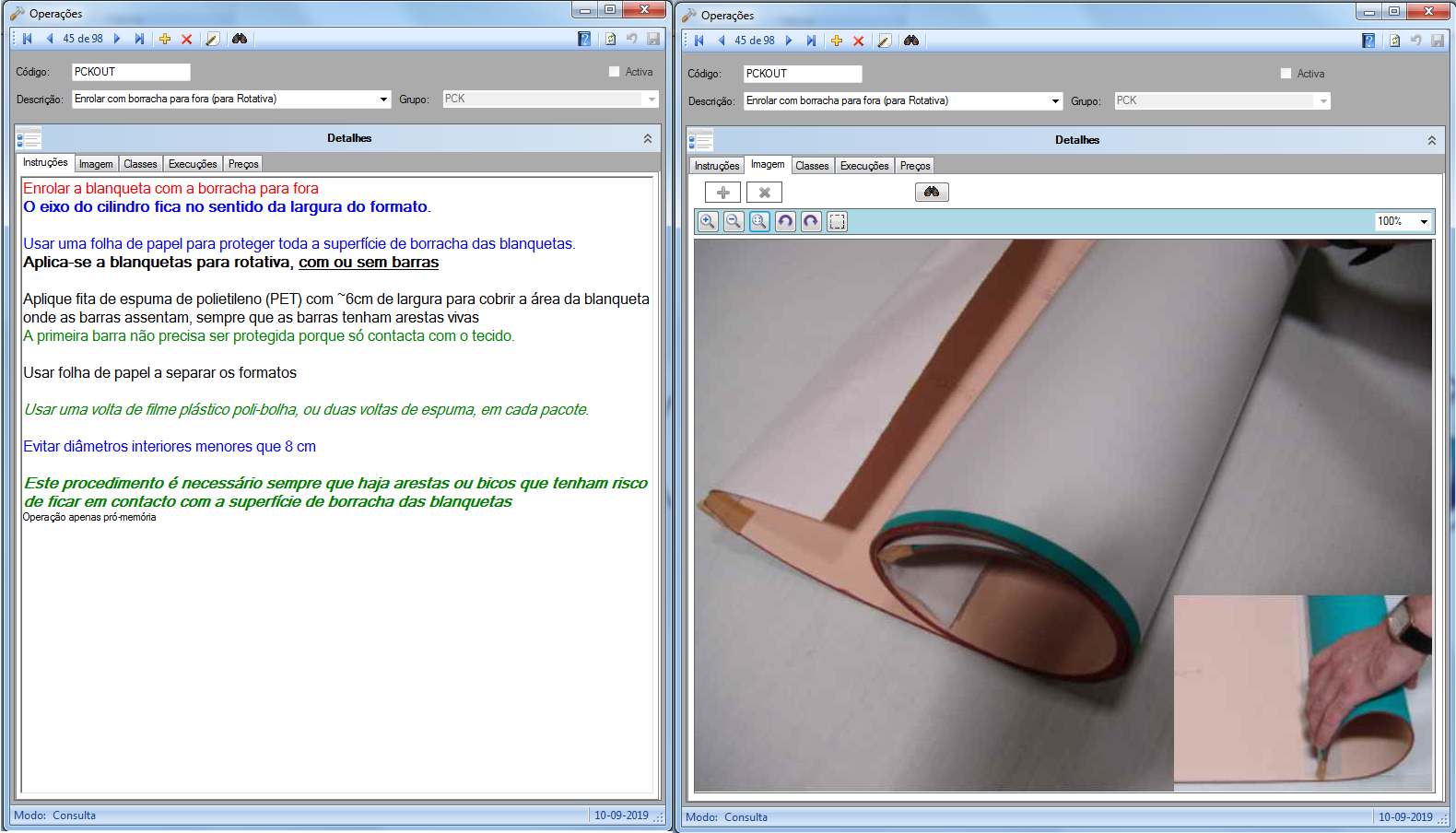

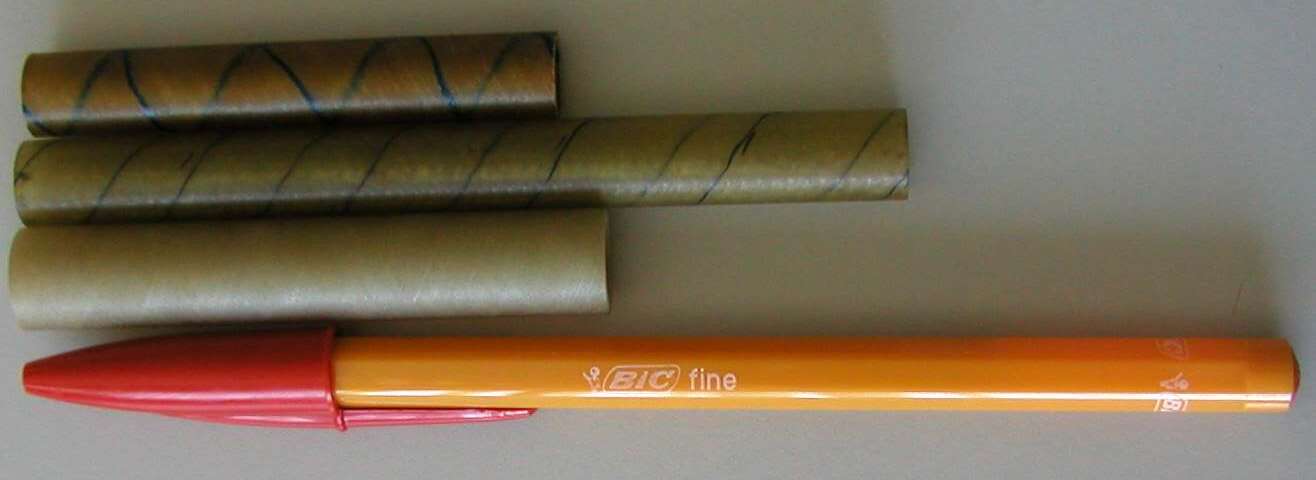

Some Narrow Gap presses use blankets with U-shaped stainless-steel bars, specially developed to meet Web Printers’ needs. These bars require the previous laser cutting of narrow strips from thin stainless steel sheets.

An assortment of spring steel flat bars and stainless steel flat bars complete our proprietary range. They cover ~90 % of our barring needs.

NOTE: Laser cutting reduces significantly the propensity of thin sheet bars to warp into a banana-like shape.

Warping tends to occur as the sheet bends into the required U-shape, the bar nose line becoming the shorter edge. Bar linearity is critical for web use.

Optimising Printing Blankets with Bars

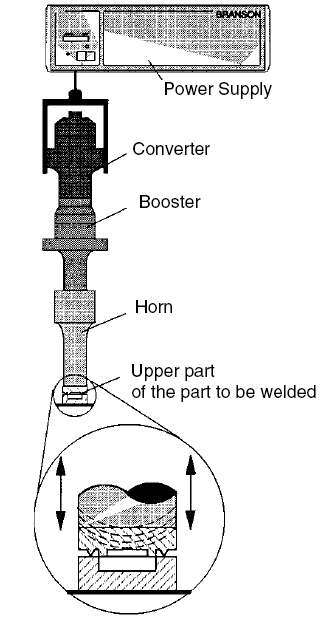

The slim profiles of IberoWIN Bar System are designed for one-way use. The press operation conveniently introduces a permanent deformation in the bar nose.

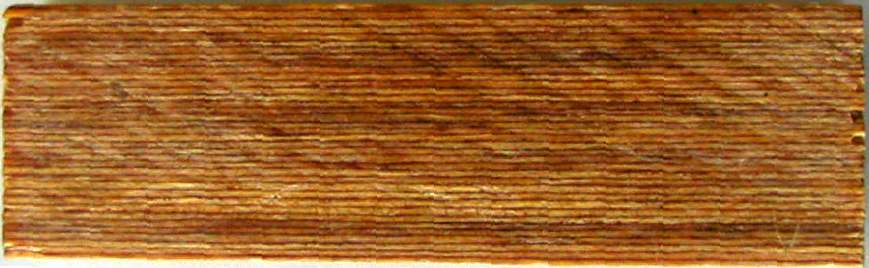

Optimal result was obtained by a combination of design factors, namely:

– The correct choice of the metal alloy.

– Adequate thermic treatment after extrusion.

– Bar surface adhesion optimisation by electric treatment.

– Design of bar leg geometrical proportions.

The desired effect has been patiently obtained by following an iterative fine tunning process. Some extrusion dies were re-machined several times to reach the desired bar performance.

This procedure warrants that extra final grip strength at the bar leg edges. But it also conveniently enables easy bar dressing on the blanket format, already fitted with a solid glue strip.

Their sturdy, but also lightweight design contribute to a comfortable format handling during the blanket cylinder dressing operation.

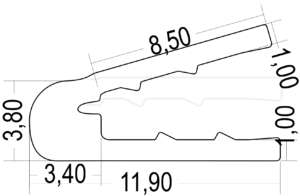

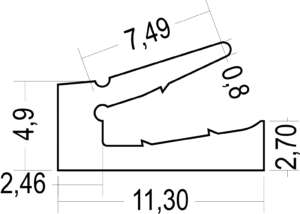

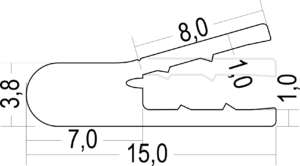

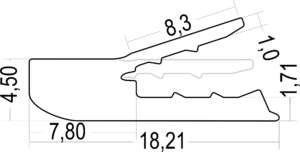

Please find here under data on our aluminium bar range.

For the sake of ease a Typical Application, only, is mentioned for each bar:

| BAR | TYPICAL APPLICATION | IMAGE |

| Asi | for Heidelberg CD/SM 102 |  |

| B2 | for KBA Rapid 142 / 164 |  |

| CDi | for old Heidelberg SORM |  |

| DZT | for older Roland 200 models |  |

| ET | for Roland 700 |  |

| Fib | for Goss Community web |  |

| GTO | for Heidelberg GTO |  |

| Lib | for Heidelberg XL 105 |  |

| Hip | for Komori Lithrone 40 |  |

| Jpi | for Akiyama |  |

| MDr | for Mailander 121 |  |

| P | for Hamada B |  |

| TKS | for TKS 9000 web |  |